KNIFE INFORMATION PAGE

| CLIP POINT The spine of a clip-point blade curves concavely or in a straight line right down from its highest point, which creates a sharp tip which is useful as a pick or for cutting in tight places. |

|

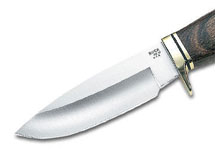

| DROP POINT A drop point blade features a convex curved drop in the point. This creates a much stronger blade tip. |

|

| DROP POINT UTILITY A drop point blade that is ground with a radius leaving a concave shape above the cutting surface. |

|

| TANTO A modified format of Japanese original sword. The front edge meets the bottom edge at an obtuse angle. A flat grind is applied to the point, leaving it extremely tough. Much cutting area is sacrificed as the trade off for tip strength. |

|

| MODIFIED TANTO A modified tanto blade is superficially similar to its original Japanese version. However, the blade has a more gently curved point and a back edge angled slightly to the point and sharpened for a short distance from the point. |

|

| SPEAR POINT A spear point blade is a symmetrically pointed blade with a point that is in line with the center line of the blade's long axis. It can have two sharpened edges, a partly sharpened second edge or a false second edge. Originally used to sharped writing quills which gave it the pen knife name. |

|

| SHEEPS FOOT This blade shape has no sharp tip and offers good control from the none sharpened back of the blade. It's a popular design for emergency rescue knives. |

|

| MIRROR POLISH Extremely meticulous and elaborate polishing operation resulting in a flawlessly bright and smooth surface. Free from scratches and blemishes, which helps to prevent rust. |

|

| HARDCASED COATING A matte scratch resistant coating with excellent corrosion protection as well as nice decorative qualities. |

|

| BLACK TINI FINISH The black titanium nitride coatings are some of the toughest coatings that can be applied to steel. They exhibit extreme hardness and are exceptionally scratch and peel resistant. |

|

| FLAT GROUND (STRAIGHT/WEDGE) A knife's edge that tapers from the cutting edge all the way to the blade's spine that is ground completely flat without a radius. |

|

| HOLLOW GROUND An edge that is ground with a radius leaving a concave shape above the cutting surface. Found on most cut throat razors. |

|

| LINER LOCK A modern design for easy one handed opening and closing. A leaf spring type liner within the groove of the handle that snaps into position under the blade when it is deployed. The lock is released by pushing the liner to the side to allow the blade to return to its groove set into the handle. |

|

| FRAMELOCK OR MONOLOCK A weight conscious update to the liner lock, which works in a manner similar to the but utilises a partial cutout of the actual knife handle, rather than a separate liner inside the handle to hold the blade in place. |

|

| AXIS LOCK An ambidextrous design, plus outstanding locking performance. |

|

| BACK LOCK A classic locking system that includes a pivoted latch affixed to a spring, and can be disengaged only by pressing the latch down to release the blade. A secure locking design with two hands required to lease the lock. |

|

| DOUBLE-CHECK LOCK A modified locking mechanism, to provide extra locking security. To release the blade, you pull the toggle back and simultaneously remove the locking liner off the pivot. Ambidextrous function and can be easily accomplished one handed. |

|

| STAINLESS STEEL Highly durable and easy to clean, top rust resistance but harder to sharpen. |

|

| MICARTA A composite of linen or paper fabric in an epoxy resin. It is incredibly lightweight, durable and visually appealing. It can be bead blasted or polished, changing its appearance. |

|

| PAKKAWOOD A waterproof plywood product, usually constructed from birch. Superbly tough and durable due to the high pressure treatment. |

|

| ALUMINUM The most common material for folding knife handles. It provides a solid handle with minimum weight added. Normal colour anodized to spec. |

|

| G10 A modern handle material made of epoxy filled with woven glass fiber that is impervious to changes in temperature. Usually black but can be other colours. |

|

| ANODIZATION Subjecting aluminum to electrolytic action which coats the aluminum with a protective / decorative film. |

|

Regardless of the cost of your knife proper care is essential to maintain optimum performance from reducing wear from use, temperature, light, moisture and oxidants. |

So preventive care is required. |

Fixed and folding blades are exclusively designed for cutting. |

It is an offence for any person, without lawful authority or good reason, to have with him in a public place, any article which has a blade or is sharply pointed [CJA 1988 section 139(1)] |

||||||||||||||||

|

||||||||||||||||

We only sell to customers that are 18 or over.CARRYING KNIVES |